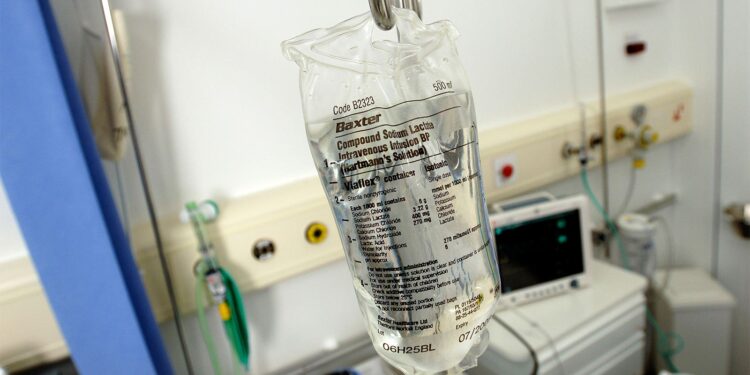

In late September, Hurricane Helene damaged a major supplier of intravenous (IV) fluids. In this report, we follow up on what has happened since.

Hurricane Helene brought unprecedented and catastrophic flooding to western North Carolina, damaging a Baxter manufacturing site that was a major supplier of IV fluids. Hospitals across the country continue to grapple with the ensuing shortage of critical supplies.

Baxter’s North Cove, North Carolina, facility provided about 60% of the IV solutions used across the U.S. as well as several other fluids vital to patient care, noted Nancy Foster, vice president of quality and safety policy at the American Hospital Association (AHA). “While remarkable progress has been made in reactivating Baxter’s plant operations, hospitals are still receiving less than their normal required amounts of these fluids.”

While the impact of the supply shortage varies across the country, “and the significance of the impact on a particular hospital depends on the methods they have been using to conserve fluids, whether Baxter was their sole supplier, the patient population they serve, and other factors,” Foster said, “we know some hospitals are still restricting access to elective surgeries, and most are using alternative strategies for hydrating patients when possible and utilizing smaller bags of fluids when appropriate.”

Though hospitals have long endured shortages of a variety of medical supplies and drugs, the shortage of IV fluids has been different, Foster told MedPage Today.

“These fluids are widely used as part of treatment for a multitude of illnesses or injuries,” Foster said in an email. “A majority of hospitalized patients receive drugs through IV infusions at least at some point during their hospital stay.”

The shortage was also unique because both the FDA and the Administration for Strategic Preparedness and Response “acted almost immediately after the hurricane damage to help expedite Baxter’s ability to get its plant operational again,” she said. “Restoration of the flow of these fluids is faster than it would have been, even if it is not as fast as we would like given that hospitals are adamant about providing the best possible care for patients, and that requires that we have the fluids our patients need.”

Baxter pointed MedPage Today to updates it has continued to issue on its progress at the North Cove manufacturing site.

In a Dec. 19 update, the company noted that it has restarted eight of the 10 manufacturing lines at the site, representing approximately 85% of total pre-hurricane capacity.

“While the recently restarted lines will require time to ramp up, some of the earlier lines to restart are operating near pre-hurricane levels,” the company noted. “We currently expect to be producing at pre-hurricane levels across the plant early in the first quarter of 2025.”

While it will “take some time for product to flow through the distribution channels,” Baxter said that “we currently expect that North Cove’s recovery to full production will translate to removal of allocations for the related product groups during the first quarter of 2025.”

Previously, in a Dec. 5 update, the company noted initial resumption of all of its 3L irrigation manufacturing lines and peritoneal dialysis solutions manufacturing lines. Baxter also previously detailed that the IV solutions manufacturing lines restarted in November produce much of the site’s pre-hurricane capacity of 1-liter IV solutions, “the most commonly used size by hospitals and clinics.”

“We anticipate [the shortage] will continue well into January,” Foster added, “but are hopeful that we will continue to see improvement along the way such that the magnitude of the problem will diminish week by week as more of Baxter’s production lines are operational and the FDA verifies that the fluids they produce are safe for use.”

Source link : https://www.medpagetoday.com/special-reports/features/113597

Author :

Publish date : 2024-12-31 16:00:00

Copyright for syndicated content belongs to the linked Source.

![author['full_name']](https://newshealth.biz/wp-content/uploads/2024/12/IV-Fluid-Shortage-Likely-to-Extend-Into-Early-2025.jpg)