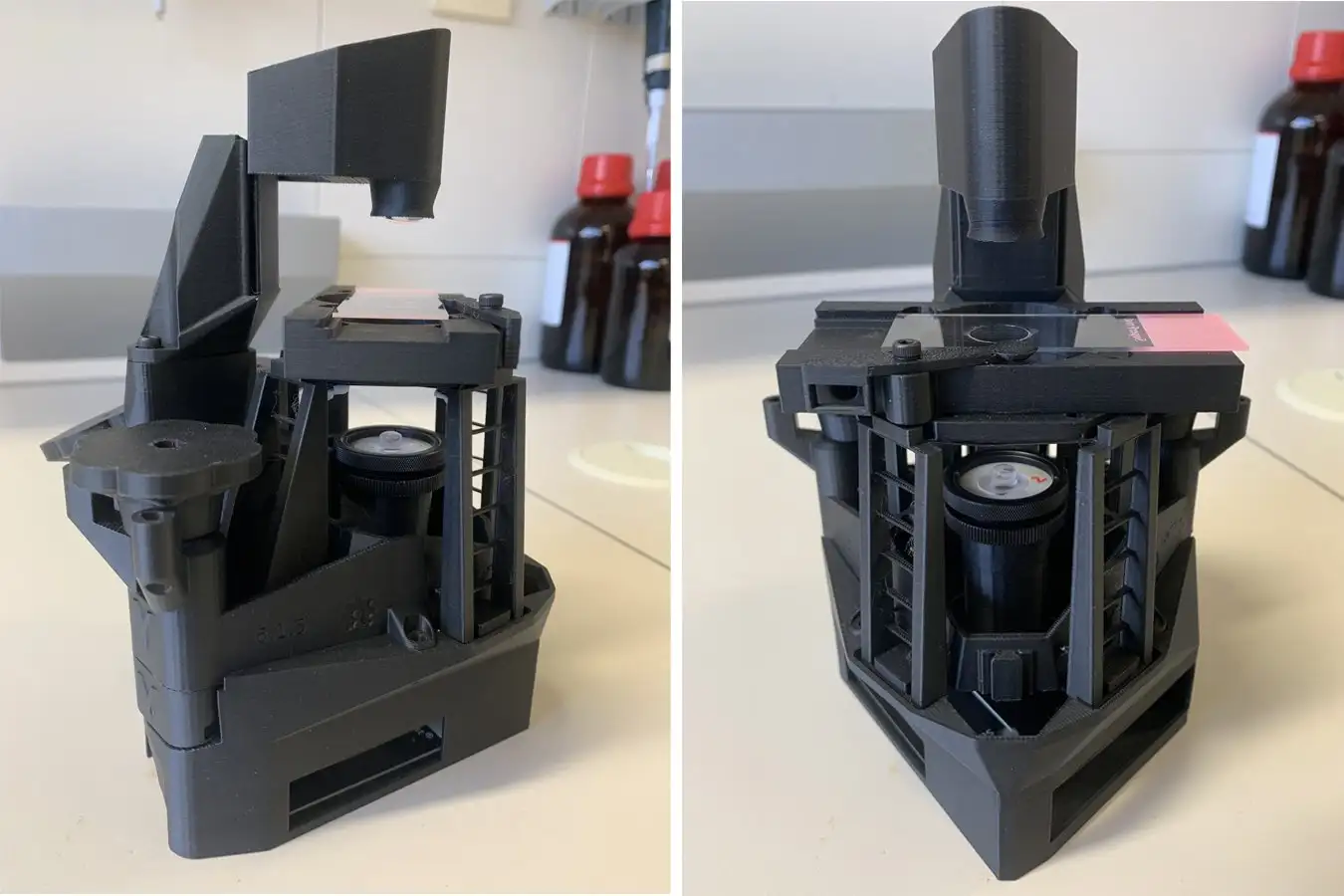

The 3D-printed microscope

Dr Liam M. Rooney/University of Strathclyde

At the beginning of 2025, a preprint of a paper about a new microscope caused an awful lot of excitement among researchers. It was the world’s first fully 3D-printed microscope, made in only a few hours and for a fraction of the typical cost.

Liam Rooney at the University of Glasgow in the UK, who worked on the project, says that after New Scientist reported on the microscope, people reached out from all over the world, from biomedical researchers to community groups and even film-makers. “Community reception was incredible,” he says. The work has now also been published in the Journal of Microscopy.

For the body of the microscope, his team used a design from OpenFlexure, which is a resource for 3D-printing scientific instruments that anyone can access. They also used a store-bought camera and a light source, while the control for all the microscope’s parts came from a Raspberry Pi computer.

The real breakthrough, however, was that the team 3D-printed the microscope’s lens out of clear plastic – this is what made their microscope both more affordable and more accessible than more conventional devices. While such microscopes can cost thousands, creating the new one cost less than £50.

“We must have printed about a thousand more lenses of different shapes since January,” says team member Gail McConnell at the University of Strathclyde in the UK.

She says several companies that make commercial products that require lenses reached out about the team’s work, as cheap and lightweight 3D-printed lenses are not at all common in large-scale manufacturing. She and her colleagues tested the microscope by examining a blood sample and a thin section of a mouse kidney, which established that it could be useful in medicine and biology studies.

But the team says their goal with the work was to democratise access to microscopes, and those dreams are coming true. They are now collaborating with a laboratory at the Kwame Nkrumah University of Science and Technology in Ghana to make microscopy more available to researchers and students in West Africa, and they have received grants from the UK Institute for Technical Skills and Strategy, says Rooney. They are also participating in programmes that upskill and empower students who face barriers to accessing education.

Additionally, the researchers have incorporated the new microscope into the Strathclyde Optical Microscopy Course, which is designed for researchers at all levels of experience and, according to Rooney, a unique educational opportunity within the UK. “This is really changing how we teach,” he says.

And there is scope for the 3D-printed microscope to become even better. The researchers have been working on improving its resolution without making it more costly, and they have already worked out how to increase its contrast by up to 67 per cent.

McConnell says that because the microscope was designed to be created with consumer electronics and accessible 3D printers, the limitations on how much it could do in the future, and how well, really lie with the limitations of current 3D-printing technology.

“As these printers get better, we will get better too: this is the bottleneck. The bottleneck is not imagination,” she says. “We are getting emails constantly from people asking us to print something new.”

Topics:

- 3D printing/

- 2025 news review

Source link : https://www.newscientist.com/article/2507677-the-worlds-first-fully-3d-printed-microscope-blew-up-in-2025/?utm_campaign=RSS%7CNSNS&utm_source=NSNS&utm_medium=RSS&utm_content=home

Author :

Publish date : 2025-12-25 11:00:00

Copyright for syndicated content belongs to the linked Source.